I heard a faint noise coming from the passenger side at ~60 km/h a few weeks ago so I jacked up the car and checked all 4 wheels as I suspected it might be a bearing. I could not detect any movement by pushing/pulling on the top and bottom of the wheel as recommended for checking the bearings, and I couldn't tell if the noises/feeling coming through the wheels was a bearing, a brake pad dragging, or gears meshing in the differential. Ended up removing the wheels and brake calipers to be sure, and the passenger rear definitely felt different than the other 3. Settled on replacing both rear bearings. I live in the middle of nowhere, so I have to take pretty much all maintenance into my own hands now!

I ordered the bearings, hardware and a Schwaben rear bearing service kit from ECS. One of the bolts came with a cracked head, which ECS replaced right away, but set me back a week.

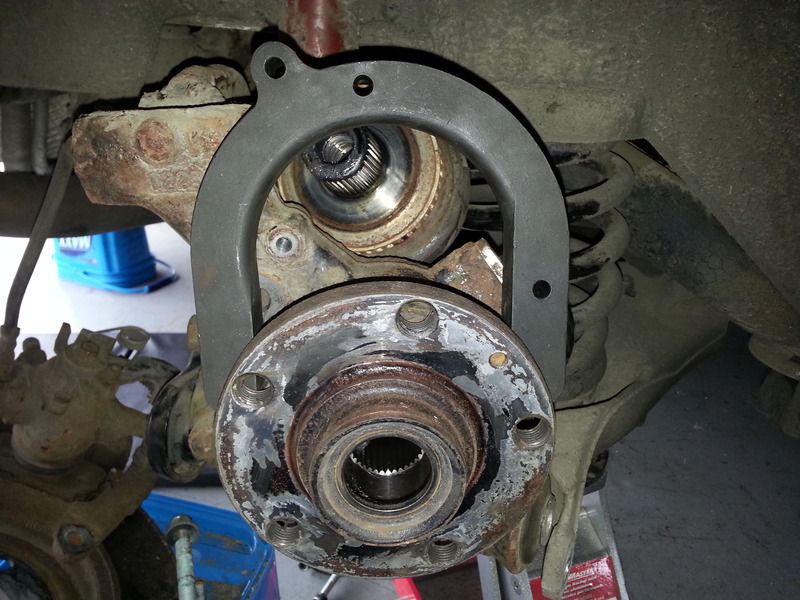

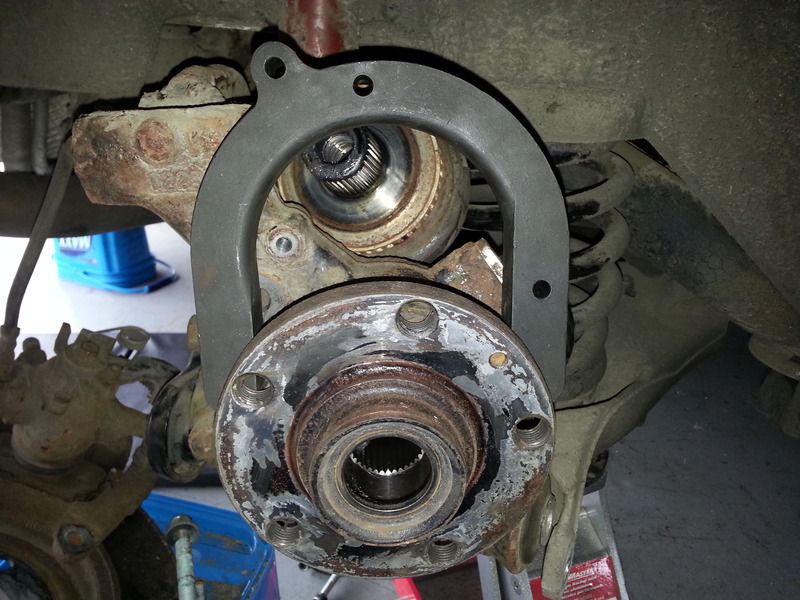

I was following the instructions provided by ECS, which are pretty comprehensive but I had some issues. I got the brakes taken off and axle removed without too much effort, although my AWE exhaust was a bit in the way for accessing some of the fasteners.

The bearing press plate from the kit did not fit over the housing so I had to open it up quite a bit (almost 1/4") to fit. Fortunately I have a machine shop at work .

.

Then the bolts for drawing the hub out did not reach the press plate, they hit on the housing too. Made it work with nuts for a shim.

After removing the hub, pulling the old bearing out (which was definitely shot) was straight forward, although I needed a 38 mm socket (called up as 32 in the instructions). Pressing the new bearing in was also easy enough, although the press plates are a little small to properly pick up on the outside race of the bearing and the instructions show the plates the wrong way which could (and did) damage the seal. At this point the hub is pressed into the new bearing. I had the plates set up as shown in the instructions. When I pressed the hub in, about halfway in it drove the inner races of the bearing out . The instructions are wrong, they have the inside press plate pick up on the housing, leaving a gap from the bearing which allowed the inner races to pop out.

. The instructions are wrong, they have the inside press plate pick up on the housing, leaving a gap from the bearing which allowed the inner races to pop out.

Fortunately I had the bearing for the other side so I was able to install it and the hub, correctly this time. Reinstalled the axle, brakes and wheel. Torqued the axle bolt - 200 N-m (150 ft-lbs) + 180 degrees, which broke my breaker bar . Total time including the modifications to the press plate was about 12 hours, MUCH longer than I had expected.

. Total time including the modifications to the press plate was about 12 hours, MUCH longer than I had expected.

I'm dealing with ECS to see what they can do for me for the work I had to do to the press plate and breaking the bearing. They offered exchange but didn't specify for what, I obviously don't want a new bearing service kit that won't fit. So far their customer service has been pretty responsive, although I didn't get any help on Saturday when I called about the plates not fitting, was just told to call on Monday to ask about return/exchange.

I ordered the bearings, hardware and a Schwaben rear bearing service kit from ECS. One of the bolts came with a cracked head, which ECS replaced right away, but set me back a week.

I was following the instructions provided by ECS, which are pretty comprehensive but I had some issues. I got the brakes taken off and axle removed without too much effort, although my AWE exhaust was a bit in the way for accessing some of the fasteners.

The bearing press plate from the kit did not fit over the housing so I had to open it up quite a bit (almost 1/4") to fit. Fortunately I have a machine shop at work

.

.

Then the bolts for drawing the hub out did not reach the press plate, they hit on the housing too. Made it work with nuts for a shim.

After removing the hub, pulling the old bearing out (which was definitely shot) was straight forward, although I needed a 38 mm socket (called up as 32 in the instructions). Pressing the new bearing in was also easy enough, although the press plates are a little small to properly pick up on the outside race of the bearing and the instructions show the plates the wrong way which could (and did) damage the seal. At this point the hub is pressed into the new bearing. I had the plates set up as shown in the instructions. When I pressed the hub in, about halfway in it drove the inner races of the bearing out

. The instructions are wrong, they have the inside press plate pick up on the housing, leaving a gap from the bearing which allowed the inner races to pop out.

. The instructions are wrong, they have the inside press plate pick up on the housing, leaving a gap from the bearing which allowed the inner races to pop out.

Fortunately I had the bearing for the other side so I was able to install it and the hub, correctly this time. Reinstalled the axle, brakes and wheel. Torqued the axle bolt - 200 N-m (150 ft-lbs) + 180 degrees, which broke my breaker bar

. Total time including the modifications to the press plate was about 12 hours, MUCH longer than I had expected.

. Total time including the modifications to the press plate was about 12 hours, MUCH longer than I had expected. I'm dealing with ECS to see what they can do for me for the work I had to do to the press plate and breaking the bearing. They offered exchange but didn't specify for what, I obviously don't want a new bearing service kit that won't fit. So far their customer service has been pretty responsive, although I didn't get any help on Saturday when I called about the plates not fitting, was just told to call on Monday to ask about return/exchange.

Comment