Was dreading taking off the crank pulley for replacement and as part of a timing belt replacement, largely because of the amount of torque on the crank bolt and the that I was missing a required tool for the job, VW 2084.

Of course the only place in town that had one was Southrape the local stealership. And they flat out refused to loan me the tool even with a $500 deposit. Then they wouldn't even entertain selling me the tool and ordering themselves in another one. Best he'd do was order it for me, at retail , and I'd still be waiting as long as I would if I'd just went through ZDMack via eBay.

, and I'd still be waiting as long as I would if I'd just went through ZDMack via eBay.

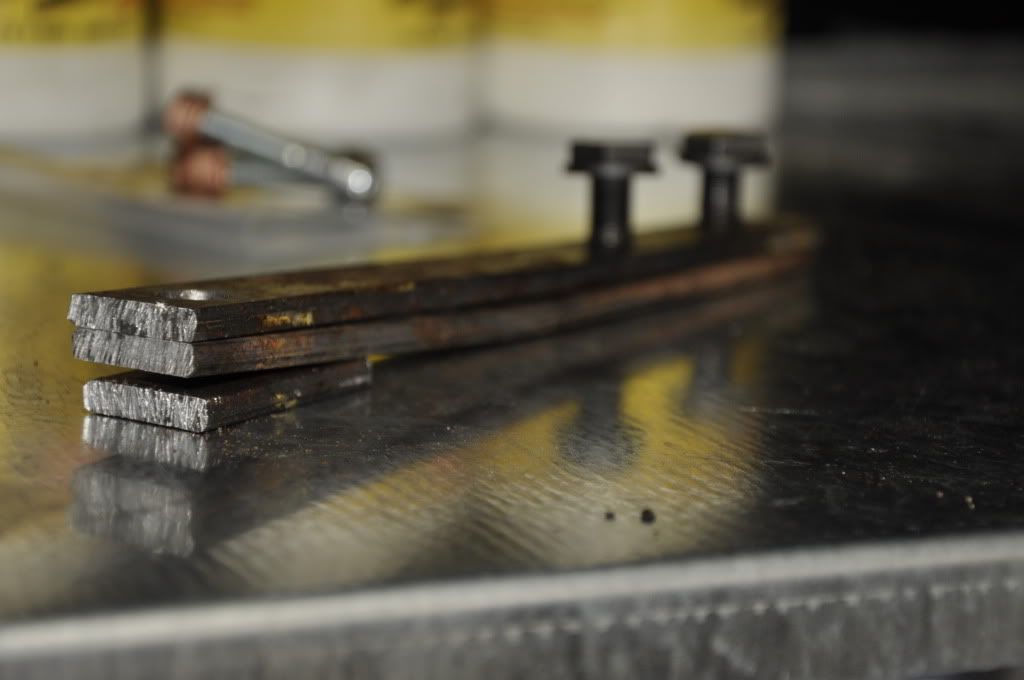

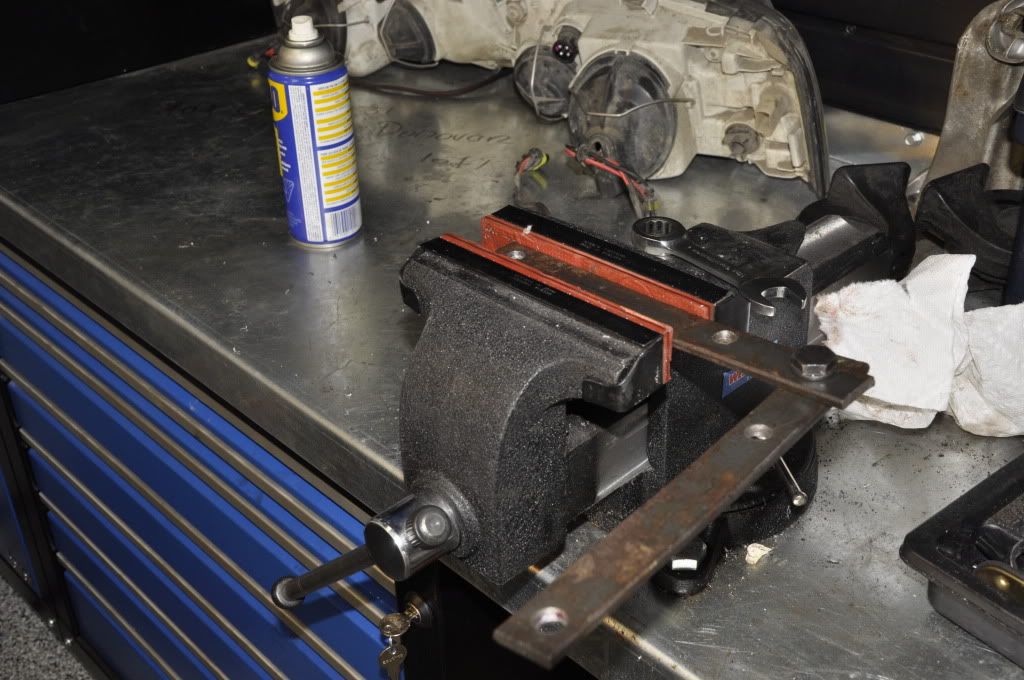

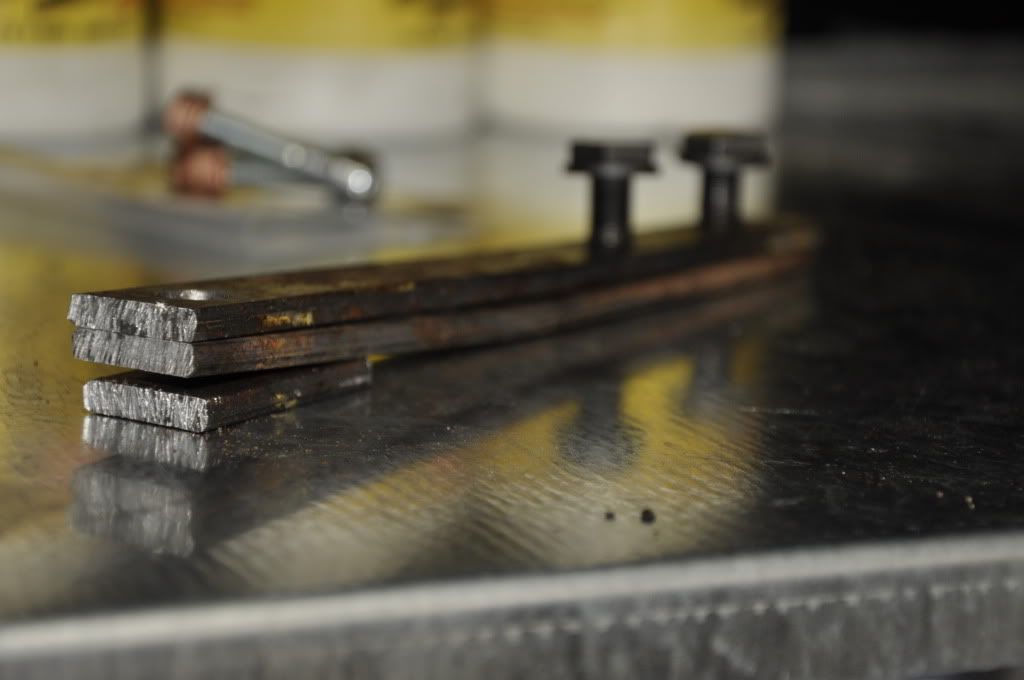

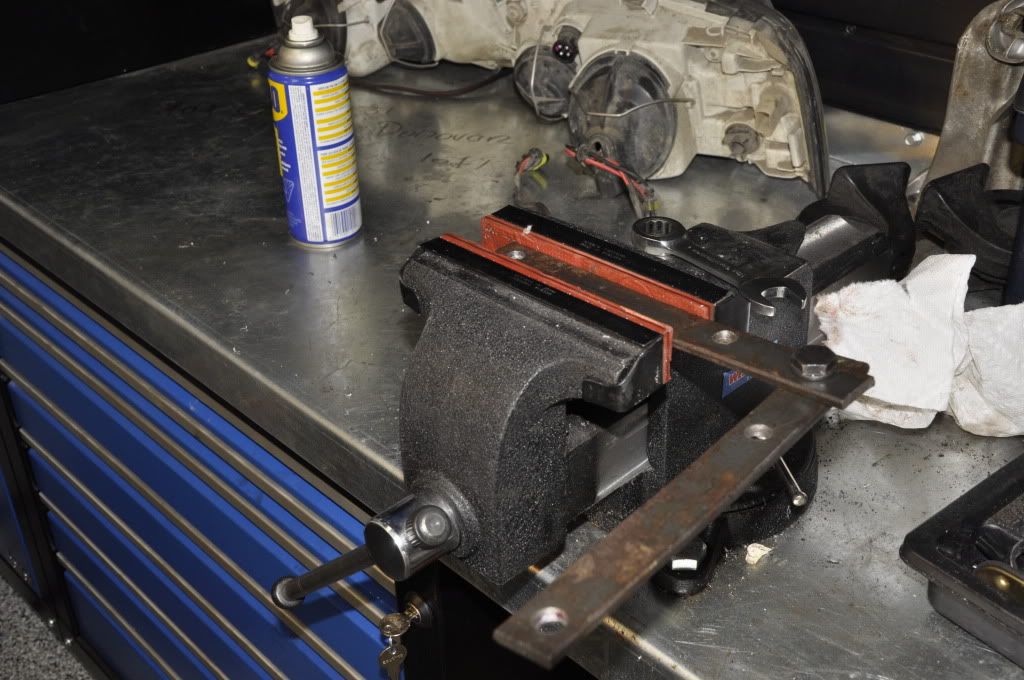

Now that it was down to principle, I said screw you I'll just make my own.

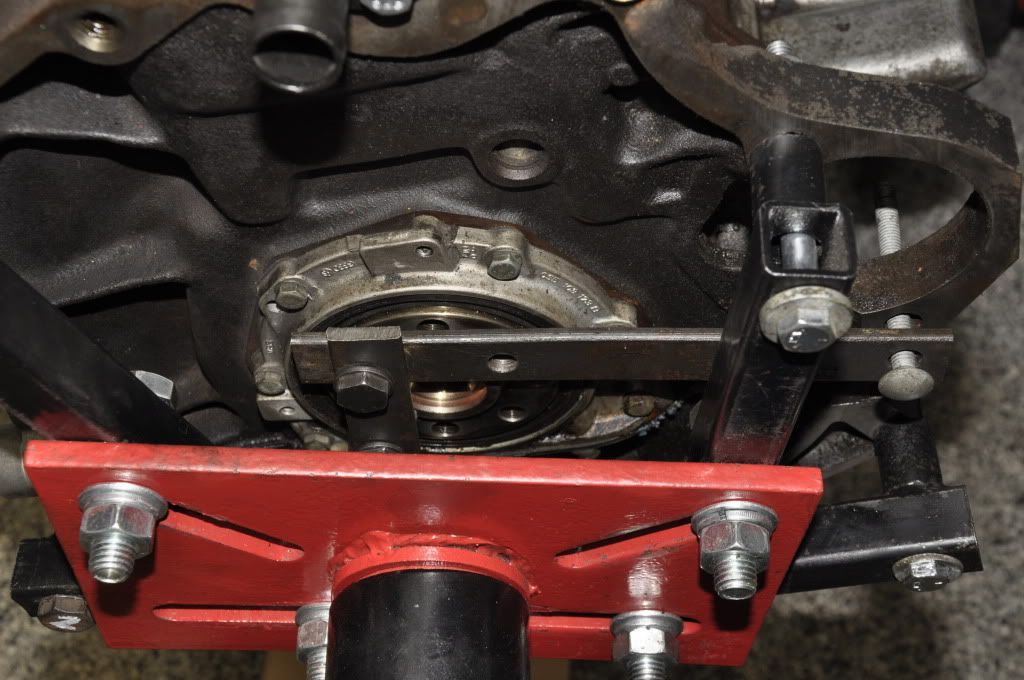

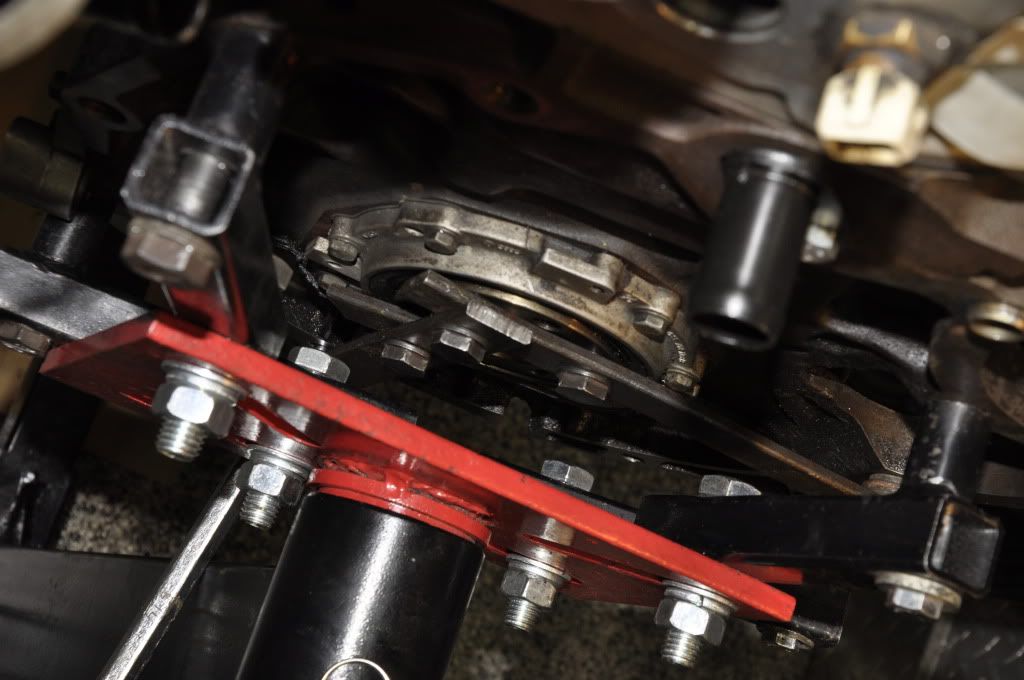

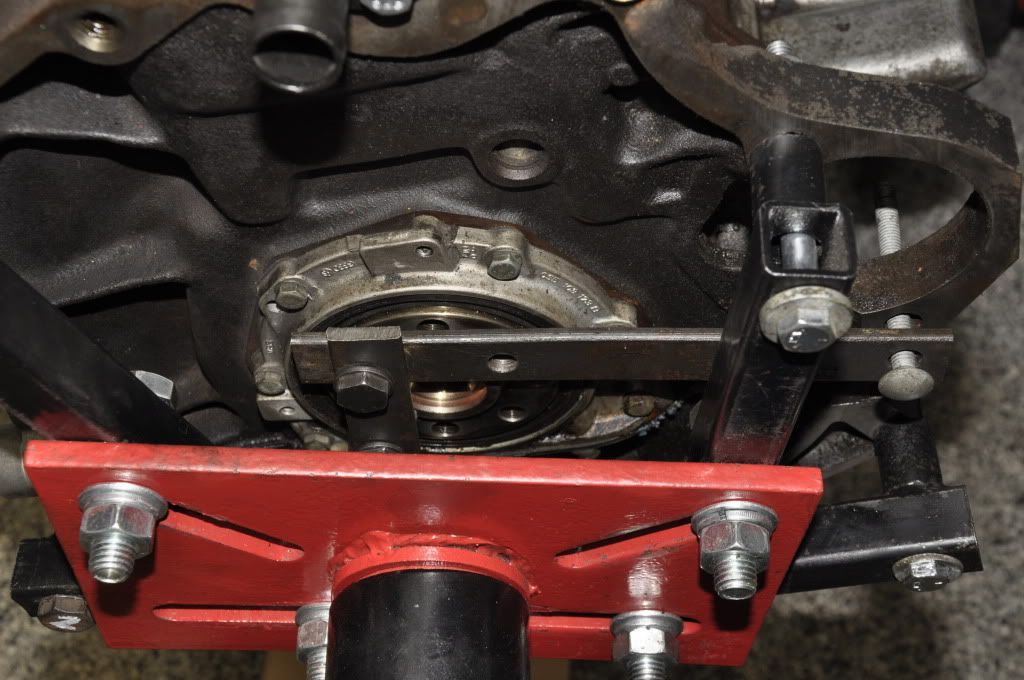

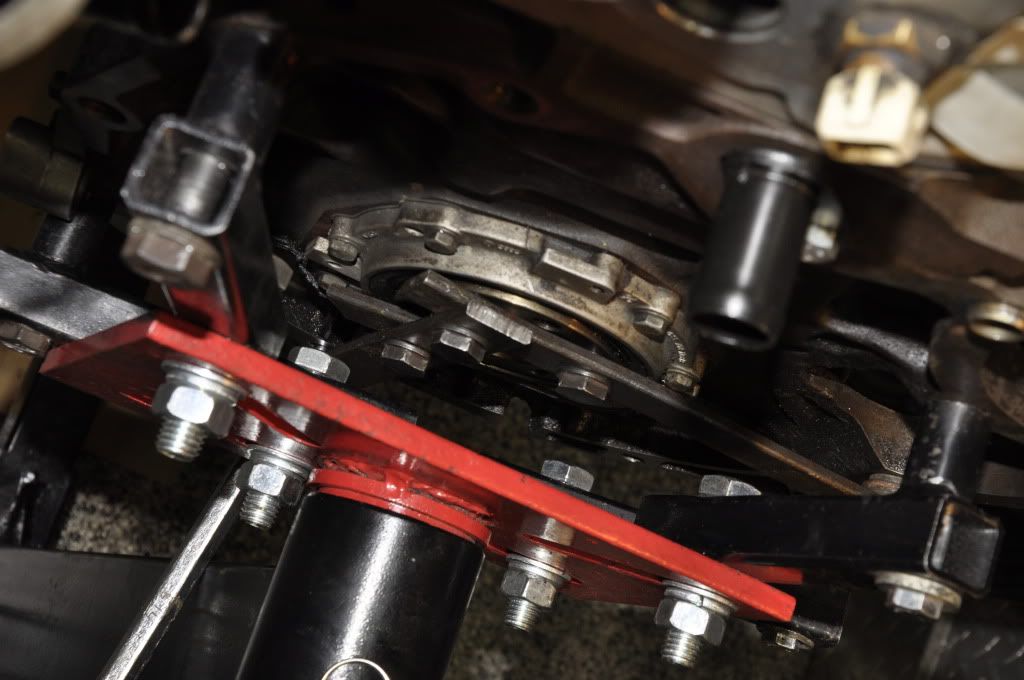

Once it was mocked up, only one original hole needed to be notched about 1/16" to fit up nicely.

The only difference was that using this flat bar tool for a crank lock out device meant you needed a person to watch the crank and make sure it doesn't drift while breaking the crank bolt. For whatever reason, this presented no issues for me and came off nice and easy. Score one for the good guys!

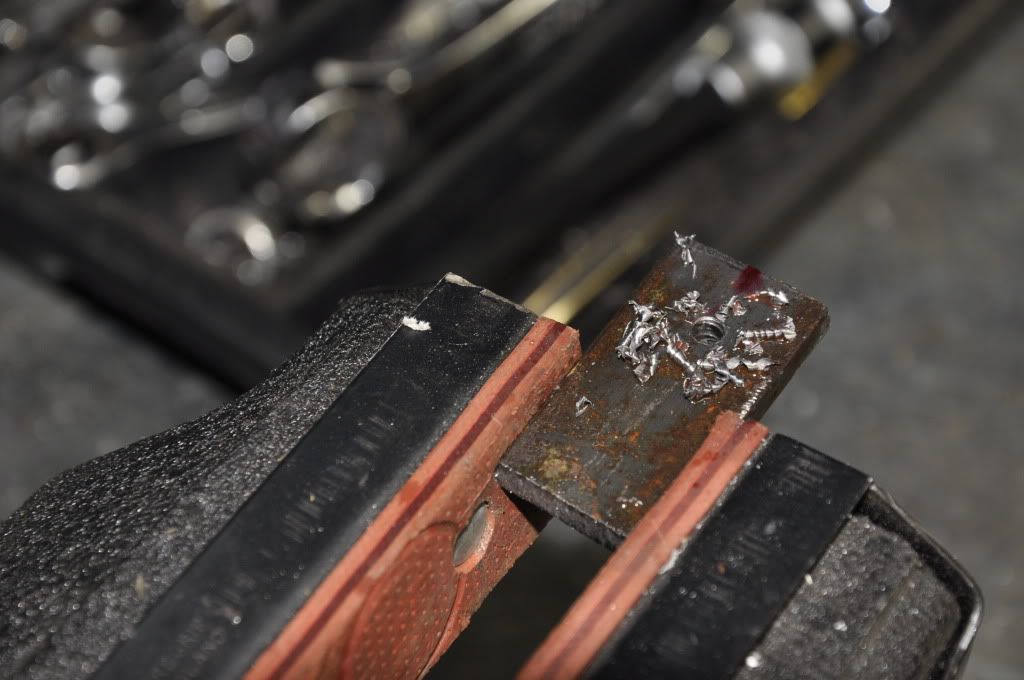

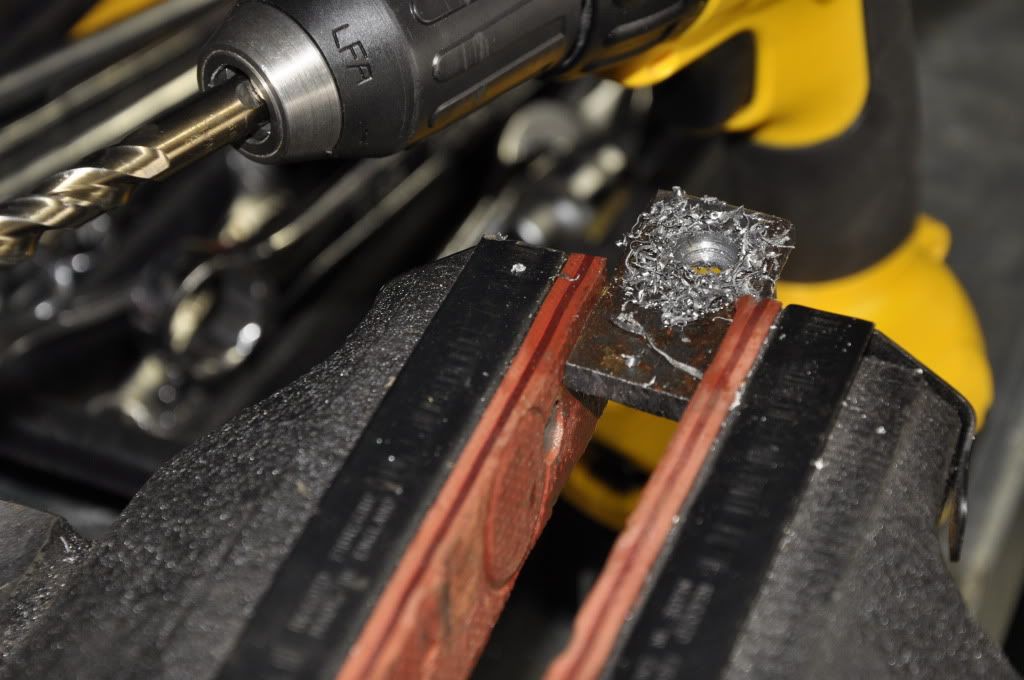

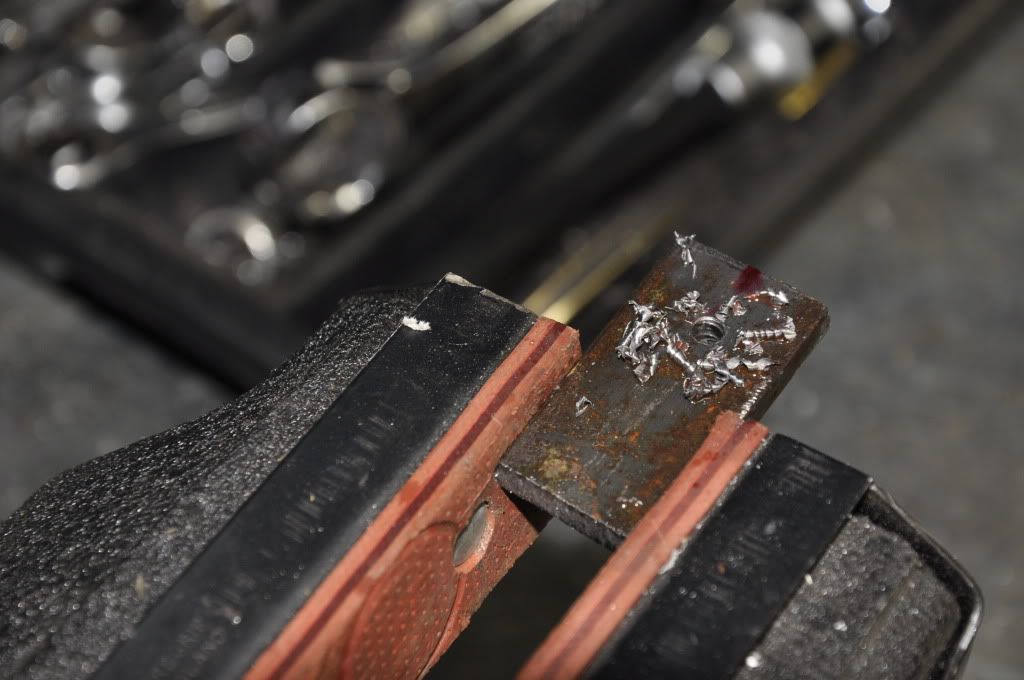

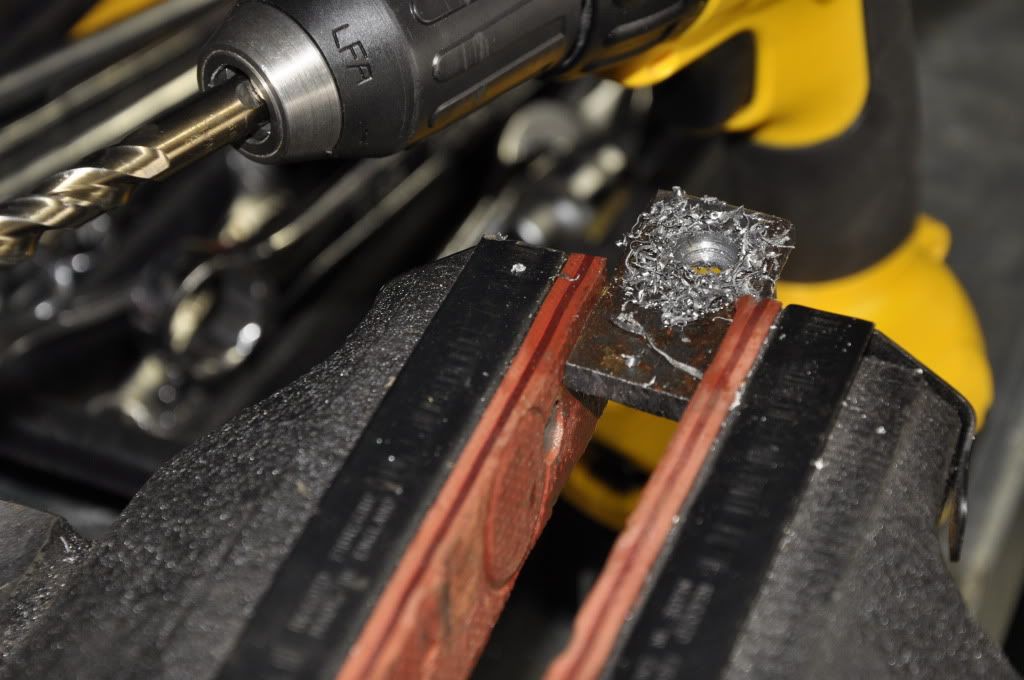

What did happen was two of the four smaller hex-head bolts that go around the crank bolt rounded during removal, so we drilled the bolt heads off and turned the studs out nice and smooth.

Same thing happened to the bolts on the outer TB cover, so using the same method to release the others, and... voila! I now have all the access I require for the work I'm about to commence.

Of course the only place in town that had one was Southrape the local stealership. And they flat out refused to loan me the tool even with a $500 deposit. Then they wouldn't even entertain selling me the tool and ordering themselves in another one. Best he'd do was order it for me, at retail

, and I'd still be waiting as long as I would if I'd just went through ZDMack via eBay.

, and I'd still be waiting as long as I would if I'd just went through ZDMack via eBay.Now that it was down to principle, I said screw you I'll just make my own.

Once it was mocked up, only one original hole needed to be notched about 1/16" to fit up nicely.

The only difference was that using this flat bar tool for a crank lock out device meant you needed a person to watch the crank and make sure it doesn't drift while breaking the crank bolt. For whatever reason, this presented no issues for me and came off nice and easy. Score one for the good guys!

What did happen was two of the four smaller hex-head bolts that go around the crank bolt rounded during removal, so we drilled the bolt heads off and turned the studs out nice and smooth.

Same thing happened to the bolts on the outer TB cover, so using the same method to release the others, and... voila! I now have all the access I require for the work I'm about to commence.

Comment