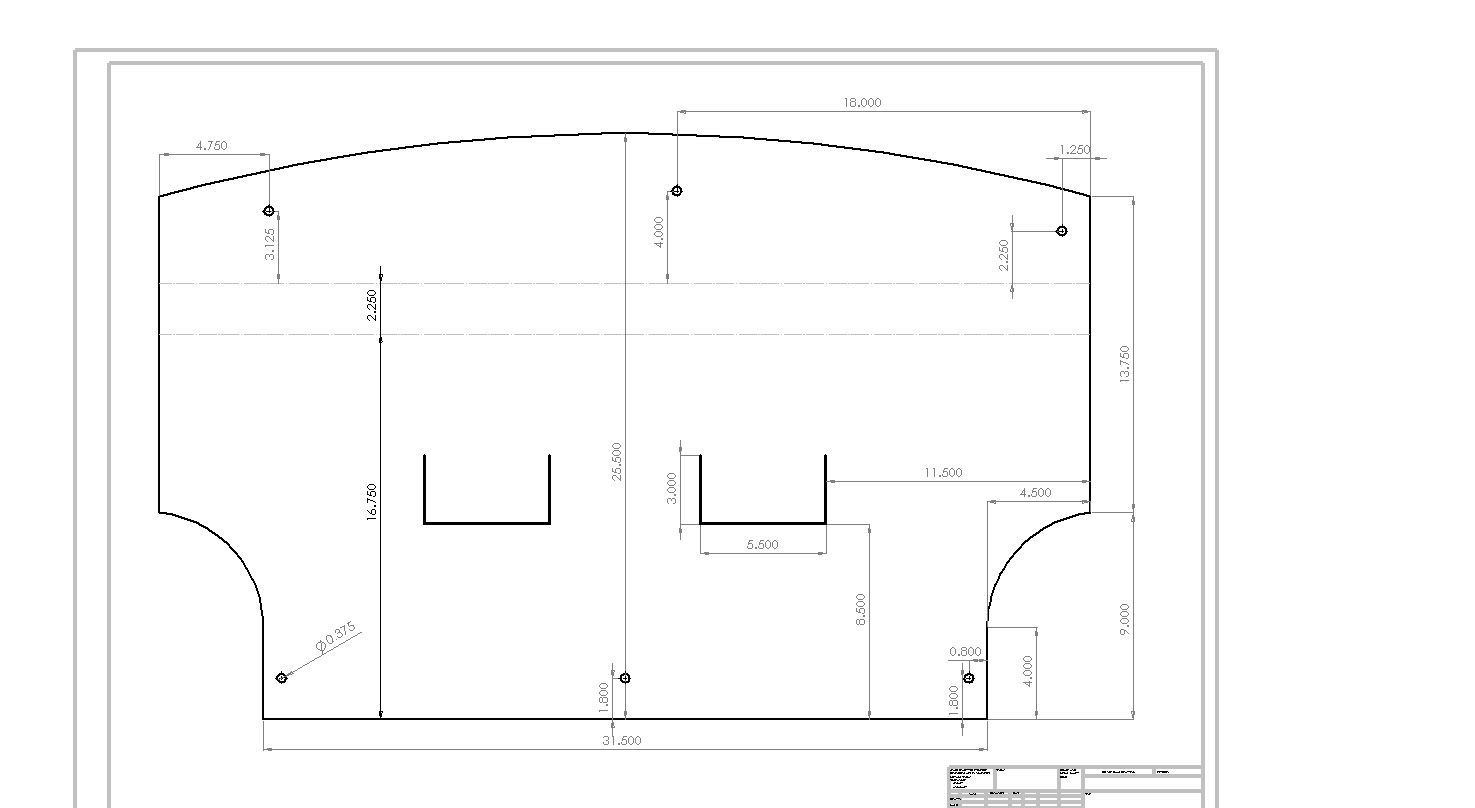

Got a few requests for the dimensions of my belly pan so I decided to make a bit of a DIY out of it.

Some iPhone shots of the final product, sorry they're not very good quality, I'll try to take better ones next time its off.

I initally made this with a cardboard template and some trial and error. After the requests I made a Solidworks model with all necessary dimensions.

I also have a high res PDF and Solidworks file if anyone is interested in them, just PM me. With the Solidworks file you could take it to a CNC shop and get the whole part cut out on a waterjet.

Although I'm 99% sure those dimensions are correct, I strongly suggest you make a cardboard template and test fit it first.

The dotted lines on the front of the bellypan are where you need to bend the metal. I bent mine so there is approximately a 3/4" step up so the pan fits under the bumper.

The diagram is a BOTTOM view of the pan, so be sure to bend the metal accordingly as the front mounting holes are NOT symmetrical. This means bend the front-most section OUT of the page, and the back-most part INTO of the page. I did this using a few c-clamps and attaching 2x4's at the top and bottom of the sheet right were the bend needs to be. Then get a couple friends to pull the whole sheet of metal until the desired bend is achieved. This is another reason to make a cardboard template first as you can test for the proper amount of bend needed.

For the vents I just Drilled holes in each corner and then used a jigsaw to cut the outline, then just bent them upwards (into the page) to emulate the OEM vents

The holes are for the OEM mounting locations on the pan, 3 at the rear, 3 at the front. Another 3 can be drilled to mount the front bumper to the pan but I found that they're not necessary.

High res image of pan here: http://s289.photobucket.com/albums/l...panhighres.jpg

All units are in inches.

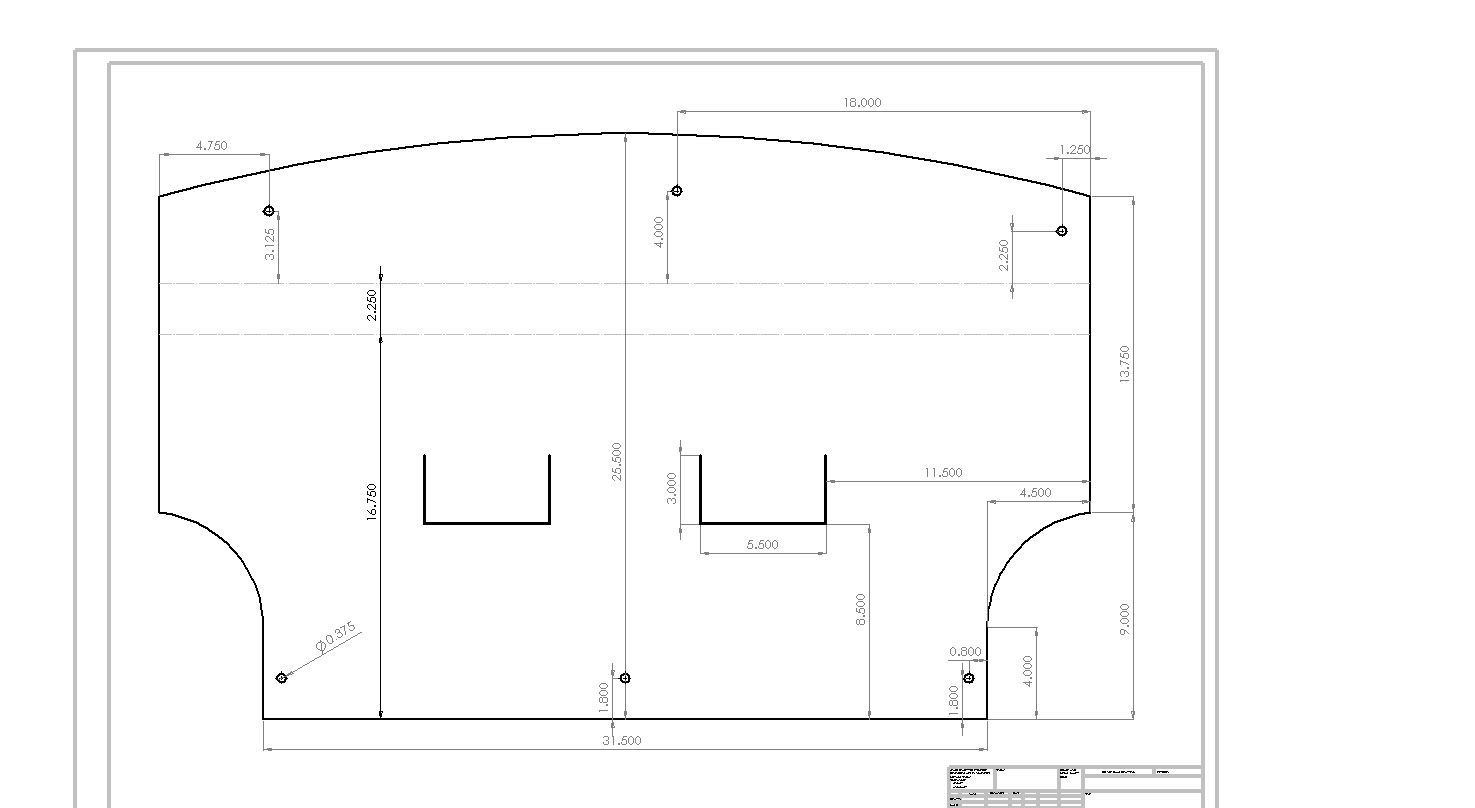

Some iPhone shots of the final product, sorry they're not very good quality, I'll try to take better ones next time its off.

I initally made this with a cardboard template and some trial and error. After the requests I made a Solidworks model with all necessary dimensions.

I also have a high res PDF and Solidworks file if anyone is interested in them, just PM me. With the Solidworks file you could take it to a CNC shop and get the whole part cut out on a waterjet.

Although I'm 99% sure those dimensions are correct, I strongly suggest you make a cardboard template and test fit it first.

The dotted lines on the front of the bellypan are where you need to bend the metal. I bent mine so there is approximately a 3/4" step up so the pan fits under the bumper.

The diagram is a BOTTOM view of the pan, so be sure to bend the metal accordingly as the front mounting holes are NOT symmetrical. This means bend the front-most section OUT of the page, and the back-most part INTO of the page. I did this using a few c-clamps and attaching 2x4's at the top and bottom of the sheet right were the bend needs to be. Then get a couple friends to pull the whole sheet of metal until the desired bend is achieved. This is another reason to make a cardboard template first as you can test for the proper amount of bend needed.

For the vents I just Drilled holes in each corner and then used a jigsaw to cut the outline, then just bent them upwards (into the page) to emulate the OEM vents

The holes are for the OEM mounting locations on the pan, 3 at the rear, 3 at the front. Another 3 can be drilled to mount the front bumper to the pan but I found that they're not necessary.

High res image of pan here: http://s289.photobucket.com/albums/l...panhighres.jpg

All units are in inches.

Comment